立式加工中心Brema

Vektor 15 - 13

立式加工中心

Brema

Vektor 15 - 13

製造年份

2019

狀況

二手

位置

Sesto Calende

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- Sesto Calende, Italy

撥打

优惠详情

- 產品ID:

- A10298021

- 參考編號:

- MHF003

- 最後更新:

- 於 18.10.2024

描述

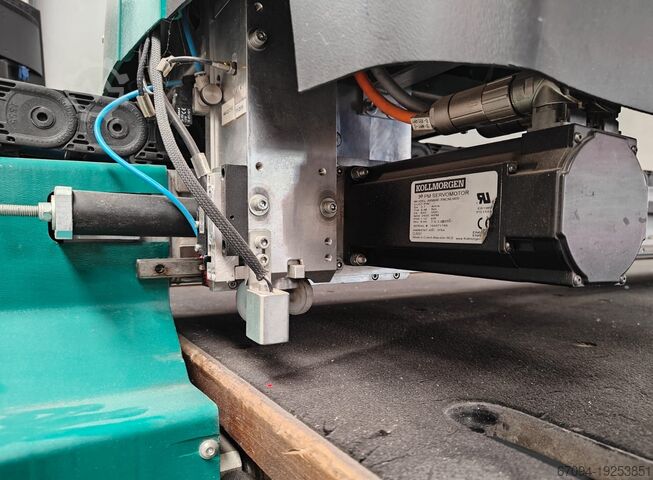

Highly flexible vertical machining center for milling, drilling and cutting. The BREMA patent for processing

vertically, allows this series of machines to be the most flexible and productive machine par excellence

to a very high quality level. Furthermore, the automatic return / rotation system of the panel makes it

fully automated.

Possibility of working in height up to 1300 mm, working on all 6 sides of the panel.

Working dimensions:

* length 300 - 2500 mm

* height 60 - 1300 mm

* thickness 10 - 80 mm

* max weight 50 kg

Machine programming and control system with PC - TPA Albatros software.

Programming editor with a high-level software interface allows you to program the machine easily and

intuitively and also allows:

* linear, circular and helical interpolation

* double zero reading

* mirror program management

* optimizer for revolver tool diameter

* optimizer for independent spindle diameter

* DXF file conversion (geometric conversion)

* import of work lists in ASCII format

* extra key for programming from the office

* gun barcode reader

* 17” LCD monitor

* Windows 7 professional operating system

Panel introduction and handling by means of motorized vertical transfer with rollers and rubber-coated pressers for sealing

of the panel during the workings, with a motorized carpet length of 2000 mm, with speed regulation

electronically adjustable with converter. The photocells and the NC program guarantee the introduction of one or more

panels in sequence using selector.

Panel height reading system consisting of an independent axis able to read the panel height

before getting into the car.

Size reading tolerance +\- 0.15 mm. In case the tolerance is exceeded a message will inform

the operator and the machine will stop the operation in progress.

Nsdpfel Ikzgex Ab Rskt

Panel thickness reading system using a mechanical feeler

Horizontal vice - M.O. axis which allows the thickness of the workpiece to be established from the program.

Vertical vice - M.V. axis which allows the program to establish the height dimension of the piece being processed.

Chain - X axis - patent double section with laser photocells able to read the reference zero of the

panel before carrying out the work.

The double section allows you to carry out machining on the lower side of the panel thus having the possibility of

work the panel on 6 sides. Brushless motors with programmable speed regulation by NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch arranged as follows:

* 7 spindles aligned in X axis

* 17 spindles aligned in Y axis

Unit driven by a high-frequency motor that allows the rotation change of the spindles up to 7000 RPM

The Brushless motor allows drilling depth control and forward speed control.

Upper revolver milling group with 10 positions and tool change controlled by NC.

11 KW motor with direct transmission of movement to the tool up to 18000 RPM. The rotation of the revolver generated by

controlled axis with Brushless motor allows quick tool change.

10 aggregate heads included in the revolver

Automatic lubrication

180° panel translation and rotation system

Movement and rotation system of the panel arriving from the machine which allows unloading or rotation

of the panel and the return to the machine for machining on both surf

vertically, allows this series of machines to be the most flexible and productive machine par excellence

to a very high quality level. Furthermore, the automatic return / rotation system of the panel makes it

fully automated.

Possibility of working in height up to 1300 mm, working on all 6 sides of the panel.

Working dimensions:

* length 300 - 2500 mm

* height 60 - 1300 mm

* thickness 10 - 80 mm

* max weight 50 kg

Machine programming and control system with PC - TPA Albatros software.

Programming editor with a high-level software interface allows you to program the machine easily and

intuitively and also allows:

* linear, circular and helical interpolation

* double zero reading

* mirror program management

* optimizer for revolver tool diameter

* optimizer for independent spindle diameter

* DXF file conversion (geometric conversion)

* import of work lists in ASCII format

* extra key for programming from the office

* gun barcode reader

* 17” LCD monitor

* Windows 7 professional operating system

Panel introduction and handling by means of motorized vertical transfer with rollers and rubber-coated pressers for sealing

of the panel during the workings, with a motorized carpet length of 2000 mm, with speed regulation

electronically adjustable with converter. The photocells and the NC program guarantee the introduction of one or more

panels in sequence using selector.

Panel height reading system consisting of an independent axis able to read the panel height

before getting into the car.

Size reading tolerance +\- 0.15 mm. In case the tolerance is exceeded a message will inform

the operator and the machine will stop the operation in progress.

Nsdpfel Ikzgex Ab Rskt

Panel thickness reading system using a mechanical feeler

Horizontal vice - M.O. axis which allows the thickness of the workpiece to be established from the program.

Vertical vice - M.V. axis which allows the program to establish the height dimension of the piece being processed.

Chain - X axis - patent double section with laser photocells able to read the reference zero of the

panel before carrying out the work.

The double section allows you to carry out machining on the lower side of the panel thus having the possibility of

work the panel on 6 sides. Brushless motors with programmable speed regulation by NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch arranged as follows:

* 7 spindles aligned in X axis

* 17 spindles aligned in Y axis

Unit driven by a high-frequency motor that allows the rotation change of the spindles up to 7000 RPM

The Brushless motor allows drilling depth control and forward speed control.

Upper revolver milling group with 10 positions and tool change controlled by NC.

11 KW motor with direct transmission of movement to the tool up to 18000 RPM. The rotation of the revolver generated by

controlled axis with Brushless motor allows quick tool change.

10 aggregate heads included in the revolver

Automatic lubrication

180° panel translation and rotation system

Movement and rotation system of the panel arriving from the machine which allows unloading or rotation

of the panel and the return to the machine for machining on both surf

这些广告您可能也感兴趣。

小广告

Lennestadt

Lennestadt

9,455 km

带直通进给的加工中心

BRE.MAVEKTOR 15-13 CNC

BRE.MAVEKTOR 15-13 CNC

小广告

Gondelsheim

Gondelsheim

9,534 km

桥式起重机大厅起重机起重机跑道起重机

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

小广告

Gościcino

Gościcino

8,669 km

玻璃切割台

GlastonUC 1000

GlastonUC 1000

小广告

Krefeld

Krefeld

9,520 km

伸缩式输送带带带输送机

BuddeTGF03

BuddeTGF03

小广告

Maasmechelen

Maasmechelen

9,594 km

玻璃切割台

Bottero353BKM-J

Bottero353BKM-J

小广告

Szczecin

Szczecin

8,939 km

紧凑型玻璃储存柜

HEGLAKPL-MZ-III, 36

HEGLAKPL-MZ-III, 36

小广告

Mühlacker

Mühlacker

9,529 km

带直通进给的加工中心

FederhennSBZ-100

FederhennSBZ-100

小广告

Sliven

Sliven

8,617 km

跨线优化

WEINIGOpticut 200 Elite

WEINIGOpticut 200 Elite

小广告

Maasmechelen

Maasmechelen

9,598 km

玻璃层压炉

FoursLamination Furnace

FoursLamination Furnace

小广告

Maulbronn

Maulbronn

9,530 km

棒材加工中心

elumatecSBZ 150

elumatecSBZ 150

您的广告已成功删除

发生错误