完整的锯木厂(固定式)WRAVOR

Banc scie horizontal OCCASION WRC 1250

完整的锯木厂(固定式)

WRAVOR

Banc scie horizontal OCCASION WRC 1250

製造年份

2020

狀況

二手

位置

Les Avenières Veyrins-Thuellin

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- 178 Route de la Romatière, 38630 Corbelin, France

撥打

技术细节

- 切割长度(最大):

- 12,000 毫米

- 总宽度:

- 1,250 毫米

- 最后一次大修年份:

- 2025

- 车轮直径:

- 1,250 毫米

- 设备:

- 驾驶室

优惠详情

- 產品ID:

- A18309481

- 最後更新:

- 於 08.12.2025

描述

EXCELLENT CONDITION, REASON FOR SALE: RENEWAL. Production since 2020 approx. 5,000 m³.

Horizontal sawmill carriage WRAVOR WRC 1250 with solid flywheels, reinforced 17m chassis for 12m cutting length.

Loading deck to feed the carriage and 8m roller outfeed conveyor: both items also available as options.

Hydraulic equipment (log clamps, log turners, and centering devices), separate control station, SIEMENS + WRAVOR cutting program, joysticks. Sawdust extraction/discharge system from the head along the entire chassis via overhead piping and hydraulic arms.

The length of the sawmill carriage is adapted to the maximum log length (with an additional device on the chassis).

Solid construction, using top-profile and special durable material for long service life.

* Rapid log centering system in the middle of the frame with hydraulic arms or hydraulic centering devices (moveable left-right, up-down).

* Hydraulic twin-cylinder grab axes move up/down, left/right and secure the log at multiple points, irrespective of log shape.

* Hydraulic rollers—move up/down (individually or all together) and rotate—for leveling the log on the carriage, advancing/retracting the log, and transporting the final board/beam from the sawmill to the outfeed conveyor (or alternative direction).

Bedpfxevr Enle Ag Selc

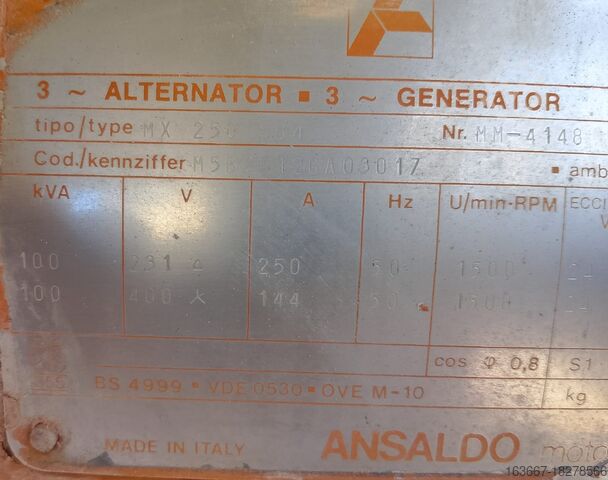

* Hydraulic generator power supply—three supply options, with or without frequency converter.

Head movement by cable (optional): more robust, precise, and easy cable replacement in case of fraying.

All mechanization and loading solutions available ON REQUEST.

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

Horizontal sawmill carriage WRAVOR WRC 1250 with solid flywheels, reinforced 17m chassis for 12m cutting length.

Loading deck to feed the carriage and 8m roller outfeed conveyor: both items also available as options.

Hydraulic equipment (log clamps, log turners, and centering devices), separate control station, SIEMENS + WRAVOR cutting program, joysticks. Sawdust extraction/discharge system from the head along the entire chassis via overhead piping and hydraulic arms.

The length of the sawmill carriage is adapted to the maximum log length (with an additional device on the chassis).

Solid construction, using top-profile and special durable material for long service life.

* Rapid log centering system in the middle of the frame with hydraulic arms or hydraulic centering devices (moveable left-right, up-down).

* Hydraulic twin-cylinder grab axes move up/down, left/right and secure the log at multiple points, irrespective of log shape.

* Hydraulic rollers—move up/down (individually or all together) and rotate—for leveling the log on the carriage, advancing/retracting the log, and transporting the final board/beam from the sawmill to the outfeed conveyor (or alternative direction).

Bedpfxevr Enle Ag Selc

* Hydraulic generator power supply—three supply options, with or without frequency converter.

Head movement by cable (optional): more robust, precise, and easy cable replacement in case of fraying.

All mechanization and loading solutions available ON REQUEST.

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

这些广告您可能也感兴趣。

小广告

Łaziska Górne

Łaziska Górne

8,830 km

主轴割草机

John Deere1905 4WD / 1 OWNER / 4200MTH!

John Deere1905 4WD / 1 OWNER / 4200MTH!

小广告

Hergensweiler

Hergensweiler

9,548 km

3轴焊接旋转台,定位器

ProtecKT 2000 HV

ProtecKT 2000 HV

小广告

Rimini

Rimini

9,559 km

发电机

ERCOLE MARELLI1312T

ERCOLE MARELLI1312T

小广告

德国

德国

9,303 km

带锯机-水平

BERG & SCHMIDX-tech 900

BERG & SCHMIDX-tech 900

小广告

Hilden

Hilden

9,512 km

带锯 - 自动

KASTOKASTOtec SC 4

KASTOKASTOtec SC 4

小广告

Oberdorf

Oberdorf

9,187 km

闸门张紧托架

Mayrhofer GmbH

Mayrhofer GmbH

小广告

Brzeźnio

Brzeźnio

8,782 km

欧元托盘生产线

ZPHU KarolexVDX3600

ZPHU KarolexVDX3600

小广告

Root

Root

9,666 km

激光雕刻机

BAUBLYSBL 65 S / NC

BAUBLYSBL 65 S / NC

小广告

Gnesau

Gnesau

9,319 km

原木堆场

Nicholson, Baljer Zembrod, Holtec, EWDRundholzplatz

Nicholson, Baljer Zembrod, Holtec, EWDRundholzplatz

小广告

Belgien

Belgien

9,697 km

成套锯木厂(固定式)

Brenta, MEM, Kallfass usw.PN1600

Brenta, MEM, Kallfass usw.PN1600

您的广告已成功删除

发生错误