线切割电火花机床(线切割数控机床)Mitsubishi

MV2400R

线切割电火花机床(线切割数控机床)

Mitsubishi

MV2400R

製造年份

2013

狀況

二手

位置

Mittweida

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- 09 Mittweida, Deutschland

撥打

技术细节

- 工件重量(最大):

- 1,500 千克

- X轴行程:

- 600 毫米

- Y轴行程:

- 400 毫米

- Z轴移动距离:

- 310 毫米

- 总高度:

- 2,150 毫米

- 总长度:

- 2,687 毫米

- 总宽度:

- 3,030 毫米

- 总重量:

- 3,500 千克

- 设备:

- 制冷单元

优惠详情

- 產品ID:

- A20742257

- 參考編號:

- MPT-108

- 最後更新:

- 於 11.12.2025

描述

Wire-Cut EDM Machine

The machine comes from productive operation and is in fully functional, used condition. All relevant assemblies are complete; the generator cabinet, control system, wire feed, and AT system (Automatic Threader) are all present and complete.

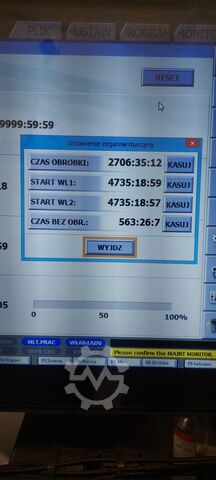

Running times according to control system:

Processing time: approx. 29,062 h

NC on-time: approx. 43,836 h

Ready-/TFT downtime: approx. 8,966 h

Maintenance records (excerpt):

Filter change: last performed at 176 h / 200 h

Resin change: 21 h / 1000 h

Oil refill: 742 h / 1000 h

Conductivity sensor: 742 h / 1000 h

Current supply rotation: 57 h / 80 h

The machine is complete but shows typical signs of use after more than 10 years in operation

Accessories are extensive and well organized

Servicing always confirmed as per control system

Automatic threading system included

Accessories / Equipment:

Original Mitsubishi nozzle & roller/bearing kit:

various guide rollers

upper and lower diamond guides

nozzle set (upper/lower nozzle)

drying stones / assembly tools

NSK/Japan replacement bearings

spare tension rollers

Manufacturer’s wooden box Mitsubishi Electric

Spare and consumables:

resin container (packed)

filter elements

quick adhesive components A/B

pH test strips

process chemicals (for EDM)

logbook / maintenance records

Documentation / manuals:

complete folders: Operator’s Manual MV Part 1 & 2

training materials “Advance Series”

operating instructions (German)

maintenance and AT maintenance sheets

Travels (X / Y / Z):

600 × 400 × 310 mm

Working table / workspace:

table size: 840 × 640 mm (square table)

Nedpfxex Hadvo Ah Aowb

max. workpiece dimensions: 1050 × 800 × 295 mm

max. workpiece weight: 1,500 kg

Wire data:

wire diameter: 0.1–0.3 mm

max. wire feed: 23 m/min

tension: 0.5–25 N

automatic threading (AT), including fine-threading

Taper cutting:

opto-linear T/C device,

±75 mm (X/Y), max. taper angle 15° at 260 mm workpiece height

Generator / Control system:

transistor-controlled pulse generator

15" LCD touch control

6-axis simultaneous control

integrated 2D and 3D CAM (Parasolid viewer)

NC memory up to 1 GB

USB interfaces (2×)

Dielectric system

tank capacity: 860 l

filter flow rate: 50 l/min

paper filters (2 pcs)

resin container 10 l (ion exchanger)

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

The machine comes from productive operation and is in fully functional, used condition. All relevant assemblies are complete; the generator cabinet, control system, wire feed, and AT system (Automatic Threader) are all present and complete.

Running times according to control system:

Processing time: approx. 29,062 h

NC on-time: approx. 43,836 h

Ready-/TFT downtime: approx. 8,966 h

Maintenance records (excerpt):

Filter change: last performed at 176 h / 200 h

Resin change: 21 h / 1000 h

Oil refill: 742 h / 1000 h

Conductivity sensor: 742 h / 1000 h

Current supply rotation: 57 h / 80 h

The machine is complete but shows typical signs of use after more than 10 years in operation

Accessories are extensive and well organized

Servicing always confirmed as per control system

Automatic threading system included

Accessories / Equipment:

Original Mitsubishi nozzle & roller/bearing kit:

various guide rollers

upper and lower diamond guides

nozzle set (upper/lower nozzle)

drying stones / assembly tools

NSK/Japan replacement bearings

spare tension rollers

Manufacturer’s wooden box Mitsubishi Electric

Spare and consumables:

resin container (packed)

filter elements

quick adhesive components A/B

pH test strips

process chemicals (for EDM)

logbook / maintenance records

Documentation / manuals:

complete folders: Operator’s Manual MV Part 1 & 2

training materials “Advance Series”

operating instructions (German)

maintenance and AT maintenance sheets

Travels (X / Y / Z):

600 × 400 × 310 mm

Working table / workspace:

table size: 840 × 640 mm (square table)

Nedpfxex Hadvo Ah Aowb

max. workpiece dimensions: 1050 × 800 × 295 mm

max. workpiece weight: 1,500 kg

Wire data:

wire diameter: 0.1–0.3 mm

max. wire feed: 23 m/min

tension: 0.5–25 N

automatic threading (AT), including fine-threading

Taper cutting:

opto-linear T/C device,

±75 mm (X/Y), max. taper angle 15° at 260 mm workpiece height

Generator / Control system:

transistor-controlled pulse generator

15" LCD touch control

6-axis simultaneous control

integrated 2D and 3D CAM (Parasolid viewer)

NC memory up to 1 GB

USB interfaces (2×)

Dielectric system

tank capacity: 860 l

filter flow rate: 50 l/min

paper filters (2 pcs)

resin container 10 l (ion exchanger)

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

这些广告您可能也感兴趣。

小广告

德国

德国

9,554 km

线切割机

MITSUBISHIMV 2400R

MITSUBISHIMV 2400R

小广告

Dieburg

Dieburg

9,473 km

五轴加工中心

POSMILLH 800 U

POSMILLH 800 U

小广告

Bielawa

Bielawa

8,947 km

线切割电火花机床(线切割EDM)

MitsubishiMV2400R

MitsubishiMV2400R

小广告

Strassberg

Strassberg

9,557 km

线切割机

MITSUBISHIMV 2400 R

MITSUBISHIMV 2400 R

小广告

Schömberg

Schömberg

9,578 km

加工中心

HERMLEC30 U

HERMLEC30 U

小广告

Herscheid

Herscheid

9,463 km

线切割机

MitsubishiMV 2400 R

MitsubishiMV 2400 R

小广告

斯洛文尼亚

斯洛文尼亚

9,281 km

线切割机床

Mitsubishi ElectricMV2400R

Mitsubishi ElectricMV2400R

小广告

Bienne

Bienne

9,733 km

线切割机(线割EDM)

CHARMILLESRobofil 440

CHARMILLESRobofil 440

小广告

Halver

Halver

9,475 km

线切割机床

MitsubishiMV2400R

MitsubishiMV2400R

小广告

Röthenbach an der Pegnitz

Röthenbach an der Pegnitz

9,350 km

线切割机

MitsubishiDrahterodiermaschine MV 2400R

MitsubishiDrahterodiermaschine MV 2400R

小广告

Lüdenscheid

Lüdenscheid

9,465 km

立式加工中心

DECKEL MAHODMU 50 T

DECKEL MAHODMU 50 T

您的广告已成功删除

发生错误