平压模、烫金、多功能GRAFOTRONIC

350 200254G

平压模、烫金、多功能

GRAFOTRONIC

350 200254G

起拍價 不包含增值稅

€67,500

狀況

二手

位置

Kruszyn Krajeński

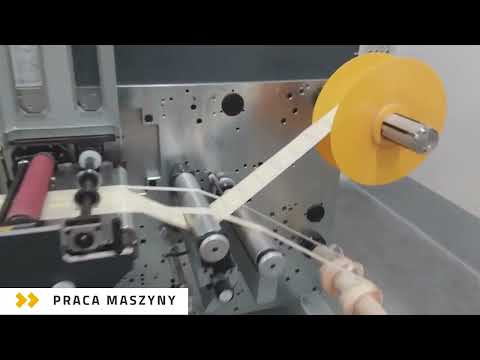

顯示圖片

显示地图

机器数据

价格和位置

起拍價 不包含增值稅

€67,500

- 位置:

- Ceramiczna 15, 86-005 Białe Błota, PL

撥打

优惠详情

- 產品ID:

- A18949116

- 最後更新:

- 於 29.12.2025

描述

Segment I – Unwinder with stabilizing table

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Pgsdpfx Aswck U Rjh Ajg

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Pgsdpfx Aswck U Rjh Ajg

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

这些广告您可能也感兴趣。

小广告

Emskirchen

Emskirchen

9,378 km

插入机

Fracotyp-PostaliaFPi 4530

Fracotyp-PostaliaFPi 4530

小广告

斯洛文尼亚

斯洛文尼亚

9,216 km

带有不停堆叠机的旋转模切

RIETSTACKIRS 430

RIETSTACKIRS 430

小广告

Budaors

Budaors

8,949 km

A3彩色复印机

Konica MinoltaC558

Konica MinoltaC558

小广告

Langenfeld (Rheinland)

Langenfeld (Rheinland)

9,513 km

数码印花机

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

小广告

Leinfelden-Echterdingen

Leinfelden-Echterdingen

9,524 km

FGT 印刷机械 - 加工

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

小广告

München

München

9,402 km

宾夕法尼亚州的Di425

Pitney BowesDI425

Pitney BowesDI425

小广告

Bad Kreuznach

Bad Kreuznach

9,533 km

柔版印刷机

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

小广告

Kaunas

Kaunas

8,309 km

雷沃

Jurmet

Jurmet

小广告

Leinfelden-Echterdingen

Leinfelden-Echterdingen

9,524 km

FGT 印刷机械 - 加工

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

小广告

Leinfelden-Echterdingen

Leinfelden-Echterdingen

9,524 km

FGT图形机械 - Labelfinisher

ROTOFLEXR 1300

ROTOFLEXR 1300

您的广告已成功删除

发生错误