型材加工中心ELUMATEC

SBZ 122/70 PLUS

型材加工中心

ELUMATEC

SBZ 122/70 PLUS

製造年份

2022

狀況

二手

位置

Zamość

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- ul. Przemysłowa 22, 22-400 Zamość, Polska

撥打

技术细节

- 转速(最小):

- 24,000 转/分

- 总重量:

- 1,635 千克

- 工具重量:

- 2,900 g

- 输入电压:

- 400 V

优惠详情

- 產品ID:

- A19049101

- 最後更新:

- 於 30.04.2025

描述

For economical and efficient machining of aluminium, plastic and thin-walled steel profiles

All machining processes such as milling, drilling and thread cutting take place on a stationary profile, protecting the profile surface

Improved work results thanks to the use of intelligent control technology

Fast positioning of the machining unit at up to 60 m/min thanks to the use of dynamic servo drives

Thread cutting without compensating chuck

Automatic clamp recognition and positioning

Lredpfxewgmyqe Ab Rsg

Automatic tool magazine with four tool shelves (without tools)

Modern, 3-axis control

Ergonomic work thanks to the use of a modern inclined bed

No need for a reference movement of the axes thanks to the use of absolute encoder-based systems

Collision avoidance thanks to automatic clamp recognition and positioning

Power-Torque milling motor with closed speed control ensures short start-up and deceleration times spindle

Certified, drive-integrated safety functions

Low power consumption thanks to intelligent control technology

Increased energy efficiency thanks to the connection of axis drives between circuits

Uninterruptible power supply (UPS)

Windows operating system

15.6" Panel PC, i3 processor, USB ports and network interface

Easy and convenient program entry via eluCam on the operator panel, even during machining

Remote online maintenance

Machine equipment

Air-cooled 8 kW milling spindle, S1

Cabin for operator protection

Four horizontal pneumatic clamps for clamping the material

Material stop, left side

HSK-F63 tool holder

Minimum quantity lubrication

High-performance coolant

Manual control panel

Depth gauge

Options

Tools

Tool holders

Automatic tool magazine for up to four standard tools

Automatic tool magazine for angle head

Rotating head HSK-F63 angle for two tools

Green-line cooling unit for control cabinet with reduced energy consumption

Barcode scanner

Protective cabin, optionally with all-round closure

Four clamps as standard. Expandable to eight clamps

Right reference material stop for placing workpieces with overlength processing

Additional stop for overlength processing on the left

Length measurement on both sides

Double clamp and additional accessories upon request

Panel PC 18.5", i5 processor

Panel PC 21.6", i7 processor

Note holder

Sound-absorbing hood

Chip disposal using chip trays

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

All machining processes such as milling, drilling and thread cutting take place on a stationary profile, protecting the profile surface

Improved work results thanks to the use of intelligent control technology

Fast positioning of the machining unit at up to 60 m/min thanks to the use of dynamic servo drives

Thread cutting without compensating chuck

Automatic clamp recognition and positioning

Lredpfxewgmyqe Ab Rsg

Automatic tool magazine with four tool shelves (without tools)

Modern, 3-axis control

Ergonomic work thanks to the use of a modern inclined bed

No need for a reference movement of the axes thanks to the use of absolute encoder-based systems

Collision avoidance thanks to automatic clamp recognition and positioning

Power-Torque milling motor with closed speed control ensures short start-up and deceleration times spindle

Certified, drive-integrated safety functions

Low power consumption thanks to intelligent control technology

Increased energy efficiency thanks to the connection of axis drives between circuits

Uninterruptible power supply (UPS)

Windows operating system

15.6" Panel PC, i3 processor, USB ports and network interface

Easy and convenient program entry via eluCam on the operator panel, even during machining

Remote online maintenance

Machine equipment

Air-cooled 8 kW milling spindle, S1

Cabin for operator protection

Four horizontal pneumatic clamps for clamping the material

Material stop, left side

HSK-F63 tool holder

Minimum quantity lubrication

High-performance coolant

Manual control panel

Depth gauge

Options

Tools

Tool holders

Automatic tool magazine for up to four standard tools

Automatic tool magazine for angle head

Rotating head HSK-F63 angle for two tools

Green-line cooling unit for control cabinet with reduced energy consumption

Barcode scanner

Protective cabin, optionally with all-round closure

Four clamps as standard. Expandable to eight clamps

Right reference material stop for placing workpieces with overlength processing

Additional stop for overlength processing on the left

Length measurement on both sides

Double clamp and additional accessories upon request

Panel PC 18.5", i5 processor

Panel PC 21.6", i7 processor

Note holder

Sound-absorbing hood

Chip disposal using chip trays

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

这些广告您可能也感兴趣。

小广告

Rödermark

Rödermark

9,470 km

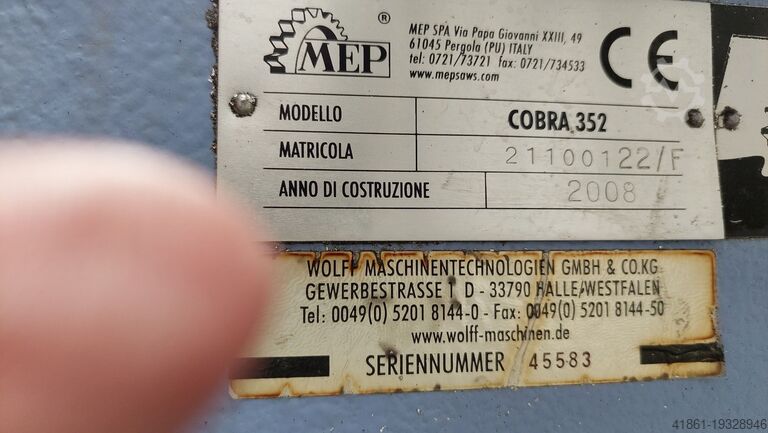

铝材斜切锯

MEPCobra 352

MEPCobra 352

小广告

Wesel

Wesel

9,505 km

振动光饰系统

ERBAEVP-A 550 Rundvibrator mit Separierung

ERBAEVP-A 550 Rundvibrator mit Separierung

小广告

Buchholz

Buchholz

9,512 km

油雾分离器

ISI Gruppe -RON 60 STR - 350 m³/h – 230 V

ISI Gruppe -RON 60 STR - 350 m³/h – 230 V

小广告

Fevziçakmak

Fevziçakmak

8,295 km

钣金去毛刺机

TFONSurfacer® TF-RB 2510

TFONSurfacer® TF-RB 2510

小广告

Zamość

Zamość

8,519 km

仿形铣床

RotoxZOR 941

RotoxZOR 941

小广告

Kruševac

Kruševac

8,955 km

全自动优化锯 9m

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

小广告

Ostrożne

Ostrożne

8,497 km

单头切断机

ElumatecMGS

ElumatecMGS

小广告

Hessisch Lichtenau

Hessisch Lichtenau

9,345 km

自动冷式斜切圆锯机、自动圆锯机、生产用锯机

KALTENBACHKKS 400 NA

KALTENBACHKKS 400 NA

小广告

Apolda

Apolda

9,250 km

双斜切锯

EmmegiPrecisionTS2 6m

EmmegiPrecisionTS2 6m

小广告

Babberich

Babberich

9,513 km

自动带锯 430 x 430 毫米

KASTOKASTOtec A4

KASTOKASTOtec A4

您的广告已成功删除

发生错误