冲压机Bobst

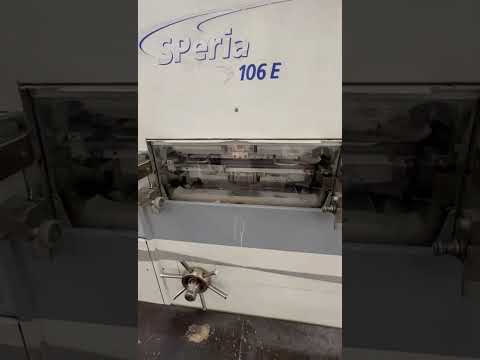

Autoplatine Speria 106 E

冲压机

Bobst

Autoplatine Speria 106 E

出厂年份

2006

状况

二手

位置

Hlavní město Praha

显示图片

显示地图

机器数据

价格和位置

- 位置:

- Jezkova 1054/10, 13000 Praha 3, Česká republika

拨打

优惠详情

- 广告编号:

- A20248585

- 更新:

- 最近更新时间为 08.12.2025

描述

Bobst Autoplatine Speria 106 E

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

Cedpfoxl Taljx Ahvogp

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

该广告为自动翻译,可能存在翻译错误。

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

Cedpfoxl Taljx Ahvogp

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

该广告为自动翻译,可能存在翻译错误。

这些广告您可能也感兴趣。

小广告

Valea Mare-Podgoria

Valea Mare-Podgoria

8,636 km

胶印印刷机

MAN Roland704

MAN Roland704

小广告

斯洛文尼亚

斯洛文尼亚

9,316 km

胶印版材处理机

Glunz & JensenTiger 125 Premium

Glunz & JensenTiger 125 Premium

小广告

德国

德国

9,303 km

制袋机

Honsel & Co.722

Honsel & Co.722

小广告

Schijndel

Schijndel

9,570 km

Ryobi 522HE(2003 年)

Ryobi522HE

Ryobi522HE

小广告

Henstedt-Ulzburg

Henstedt-Ulzburg

9,184 km

切纸机

PolarN 115 PLUS

PolarN 115 PLUS

小广告

Radom

Radom

8,627 km

切纸机

Wohlenberg 132 TSPaper Cutting Machine

Wohlenberg 132 TSPaper Cutting Machine

小广告

Alsfeld

Alsfeld

9,399 km

自动冲孔机

BobstSP142ER

BobstSP142ER

小广告

Zaandam

Zaandam

9,557 km

MBO折纸机

MBOK 66 KL/6

MBOK 66 KL/6

小广告

Wuppertal

Wuppertal

9,491 km

织带机 4/42mm

Jakob Müller Frick AGNF42 4/42mm

Jakob Müller Frick AGNF42 4/42mm

小广告

Zaandam

Zaandam

9,557 km

胶印印刷机

HeidelbergXL 75-5 P F UV

HeidelbergXL 75-5 P F UV

您的广告已成功删除

发生错误